wpc micro shot peening

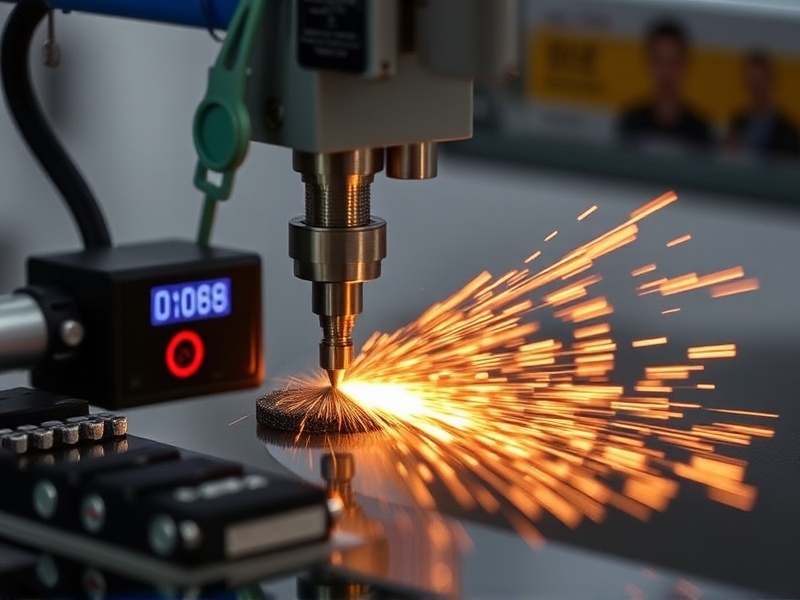

Introduction to WPC Micro Shot Peening

WPC Micro Shot Peening (WPC MSP) is a surface treatment technique that enhances the fatigue life and wear resistance of metal components by introducing compressive residual stresses on their surfaces. This method has gained significant attention due to its ability to improve the mechanical properties of materials without altering their dimensions or geometry. The process involves bombarding the surface of a workpiece with tiny spherical particles at high velocities, creating small indentations that result in a layer of compressive stress. This article delves into the fundamental principles of WPC Micro Shot Peening, covering its process, the equipment used, and its typical applications in various industrial settings.

The Process of WPC Micro Shot Peening

The WPC Micro Shot Peening process begins with the preparation of the workpiece, ensuring it is clean and free from contaminants that could interfere with the peening process. The next step involves selecting appropriate shot material, typically made from steel, ceramic, or glass, depending on the hardness and strength requirements of the application. The selected shot is then accelerated using compressed air or mechanical means to impact the surface of the workpiece at high speeds, creating a uniform pattern of small indentations. These impacts introduce compressive stresses on the surface, which are crucial for enhancing the fatigue life and wear resistance of the component. The depth and distribution of these compressive stresses can be controlled by adjusting parameters such as shot size, velocity, and coverage density.

Equipment Used in WPC Micro Shot Peening

The equipment used in WPC Micro Shot Peening includes a blasting cabinet or chamber where the workpiece is placed, a system for delivering the shot material, and a mechanism for accelerating the shot. Modern systems often incorporate automated controls for precise adjustment of parameters like shot velocity and coverage density, ensuring consistent results across multiple parts. Additionally, specialized nozzles are used to direct the flow of shot material, allowing for targeted peening of specific areas of the workpiece. Safety features such as protective barriers and dust collection systems are also integral components of the setup, safeguarding operators from potential hazards associated with the process.

Typical Applications in Industrial Settings

WPC Micro Shot Peening finds extensive use in industries where the integrity and longevity of metal components are critical. Aerospace manufacturers employ this technique to enhance the fatigue resistance of turbine blades and engine components, thereby extending their operational lifespan. In automotive engineering, it is utilized to improve the durability of transmission gears and suspension parts subjected to cyclic loading. Furthermore, the medical device industry benefits from WPC Micro Shot Peening through the production of implants with enhanced biocompatibility and corrosion resistance. By reducing the risk of surface defects and stress concentrations, this process contributes significantly to the overall reliability and performance of these components.

Reference Literature

Micro Shot Peening Process for Surface Finishing and Fatigue Life Improvement

Surface Treatment Techniques for Enhancing Mechanical Properties of Metals

Reviews

There are no reviews yet.